The ultrafiltration

June 28, 2022

Sports Demo Day 2022 in Lindau

July 1, 2022Ultrafiltration in industry

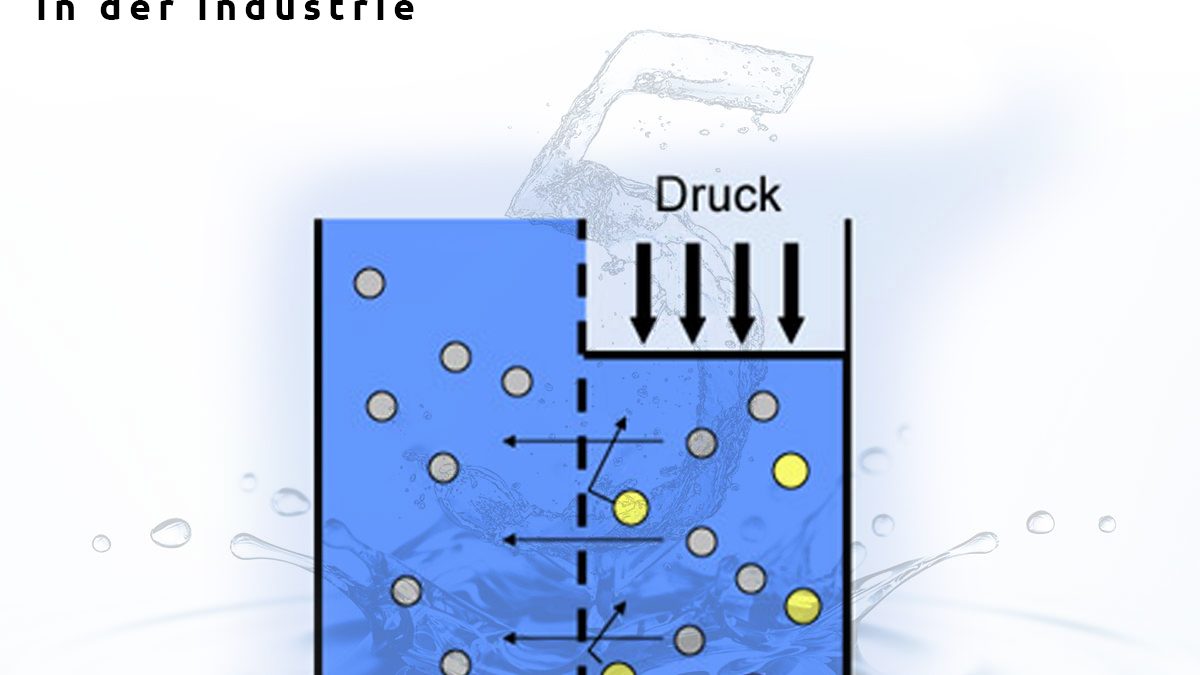

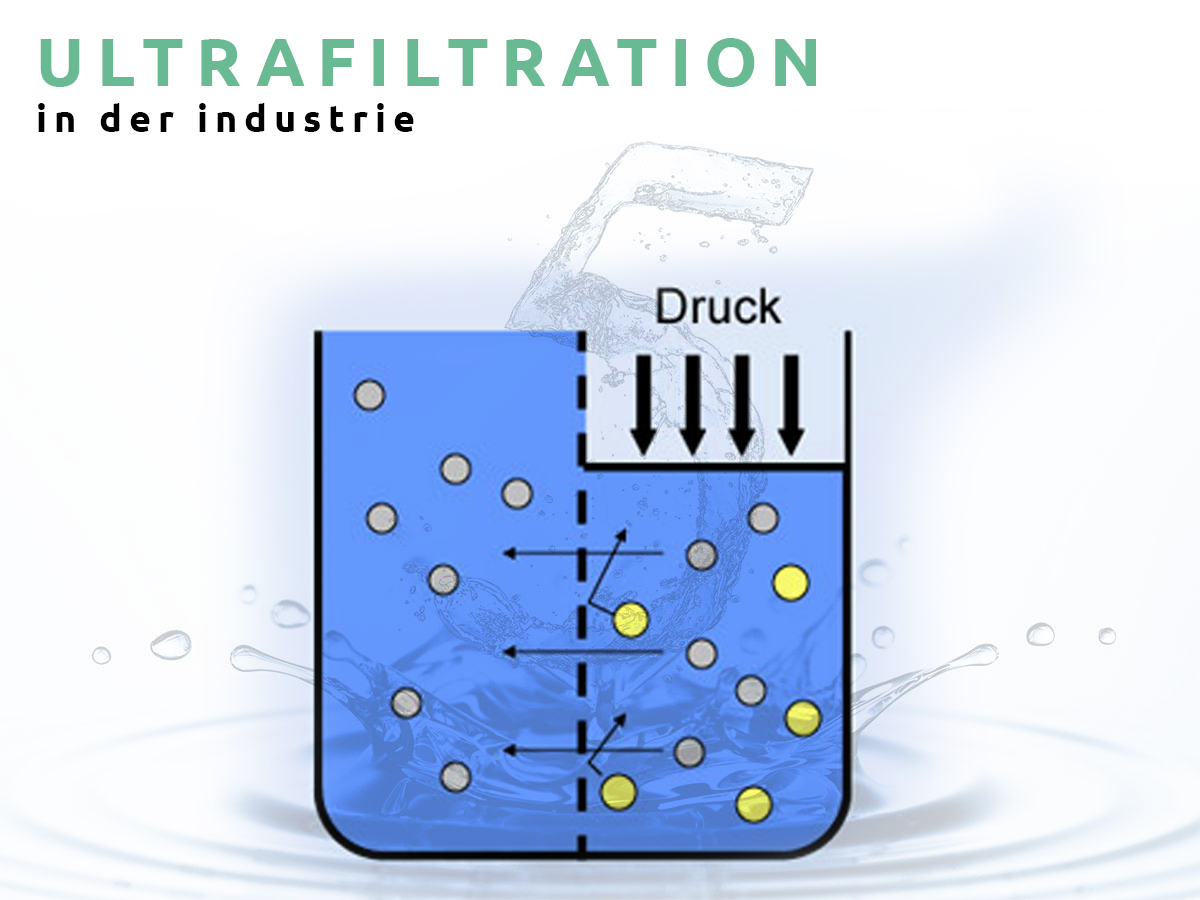

Ultrafiltration (UF) is primarily a particle size-dependent, pressure-driven mass separation process based on a sieving effect.

Ultrafiltration membranes have a pore size between 1 nm and 100 nm and are thus capable of retaining compounds with a molecular weight of 300 Daltons to 500,000 Daltons. This typically makes the process suitable for the retention of biomolecules, bacteria, viruses, polymers, colloidal particles and sugar molecules.

One describes ultrafiltration membranes by their nominal molecular weight cutoff (MWCO). The MWCO usually represents the smallest molecular weight for which the membrane has a retention greater than 90%. In many cases, however, the separation result is not exclusively influenced by the cutoff but additionally by interactions between the membrane and the raw solution. The operating pressure of an ultrafiltration is usually between 0.1 and 1 MPa, usually performing one of the following tasks:

- Clear filtration of a crude solution

Concentration of substances

Fractionation of substances

Sufficient separation of substances in the fractionation of dissolved substances or in the separation of dissolved substances and solvents is achieved when the size of the particles differs at least tenfold. Today, one can find different applications of ultrafiltration in almost all industrial sectors:

- sterile filtration of drinking and beverage water

Surface water treatment

Recovery of filter backwash water

Separation of oil/water emulsions

Recovery of electrophoretic coatings